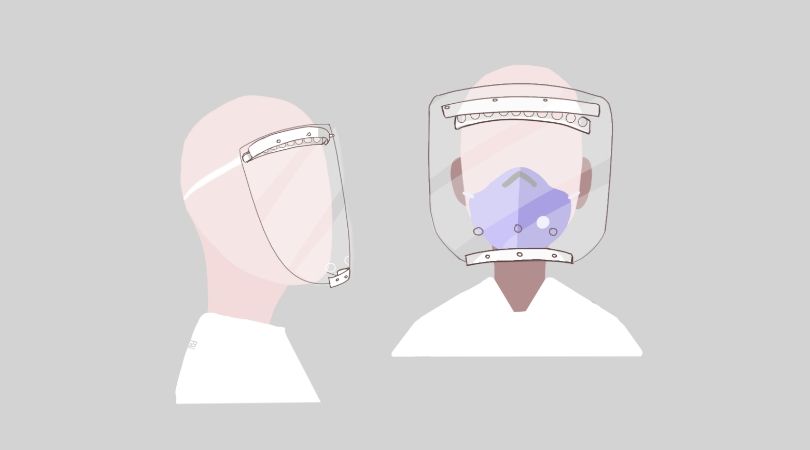

Researchers, universities, entrepreneurs, and volunteers from all over Brazil are joining initiatives to produce personal protective equipment (PPE) for hospitals using 3D printing, in an attempt to better protect health professionals on the frontline of the Covid-19 outbreak

The initiatives come at a moment PPE shortages not only in Brazil, but worldwide amid the coronavirus pandemic. A report from weekly news magazine show Fantástico, from Globo TV, says that the Brazilian Medical Association (AMB) and the National Nursing Council have received roughly 4,000 complaints and inspection requests due to shortages and professionals working without the proper equipment in the past two weeks.

And while the lack of resources is a well-known issue in public hospitals, even private institutions are showing signs of strain. According to news website UOL news website, Hospital Albert Einstein, a leading institution in Brazil, is also restricting the use of PPE among its staff.

The AMB has created a platform to receive complaints and, as of March 29, 2,513 reports of PPE shortages were registered in the country.

On March 30, the Health Ministry reported it had already shipped resources to the most affected states, such as São Paulo and Rio de Janeiro, including 14.2 million surgical masks, 24 million gloves for non-surgical procedures, 742,000 aprons, 290,000 scrub caps, 168,000 bottles of alcohol disinfectant, 100,000 shoes, and 60,000 pairs of protective glasses, and it says it is working to procure millions of...

Search

Search